What Are You Looking For?

Baffle Plate Manufacturer Changrun Supplies Forged Baffle Plate/ Support Plate.

Size: φ254.5*6mm

Material: Q235B

Lagest Forging: 100MT.

Max OD: 8 Meters.

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

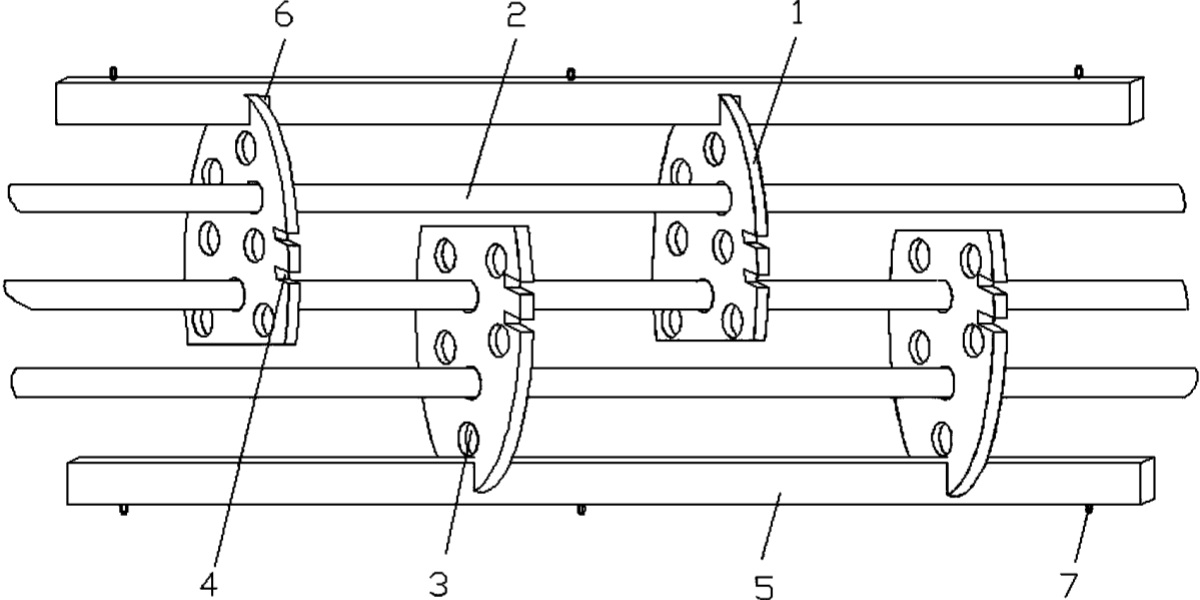

Baffles plate are an integral part of the shell and tube heat exchanger design. A baffle is designed to support tube bundles and direct the flow of fluids for maximum efficiency. Baffles can come in various forms and designs, depending on the specific application and requirements.

The principle of baffle is based on fluid mechanics and the law of conservation of momentum. By designing the shape, angle, and position of the baffle reasonably, the desired fluid control effect can be achieved. The shape and angle of the baffle can affect factors such as fluid diversion, turbulence generation, and velocity changes. Therefore, when designing a baffle, it is necessary to consider the properties of the fluid, flow rate, pressure, and required control effects.

The workers bevelled the holes and polished the edges of the baffle plate.

Baffles are commonly used in tubular heat exchangers and are heat exchange devices commonly used in industrial sectors such as metallurgy, chemical industry, machinery, energy, transportation, light industry, and food. Tubular heat exchangers are suitable for different working conditions such as cooling, condensation, heating, evaporation, and waste heat recovery.

Materials:

Stainless Steel & Duplex Steel: ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254)

ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L

Carbon Steel: ASTM/ASME A105, SA182 F1、F5、F9、F11、F12、F22、F51、A350-LF3

Nickel & Nickel Alloy: Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36

Titanium & Titanium Alloy: ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12, ASTM B381 F1, F2, F7, F12

Copper & Copper-Nickel: C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu)

Clad Materials: Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet