What Are You Looking For?

Forged Blind Flange Manufacturer Changrun Supplies Forged BL Flanges,

Dimension: 2 Inch (DN50)

Class rating: 150lb

Material: ASTM A182 F316

Flange face: RF

Certificates: CE, ISO, PED, TS, BV, CQC.

ASME B16.5 Class 150

RF Blind Flange

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 88.9 | 11.2 | 35.1 | 4 | 15.7 | 1/2 | 60.5 | 0.5 |

| 3/4 | 98.6 | 12.7 | 42.9 | 4 | 15.7 | 1/2 | 69.9 | 1 |

| 1 | 108 | 14.2 | 50.8 | 4 | 15.7 | 1/2 | 79.2 | 1 |

| 1-1/4 | 117.3 | 15.7 | 63.5 | 4 | 15.7 | 1/2 | 88.9 | 1 |

| 1-1/2 | 127 | 17.5 | 73.2 | 4 | 15.7 | 1/2 | 98.6 | 2 |

| 2 | 152.4 | 19.1 | 91.9 | 4 | 19.1 | 5/8 | 120.7 | 2 |

| 2-1/2 | 177.8 | 22.4 | 104.6 | 4 | 19.1 | 5/8 | 139.7 | 3 |

| 3 | 190.5 | 23.9 | 127 | 4 | 19.1 | 5/8 | 152.4 | 4 |

| 3-1/2 | 215.9 | 23.9 | 139.7 | 8 | 19.1 | 5/8 | 177.8 | 6 |

| 4 | 228.6 | 23.9 | 157.2 | 8 | 19.1 | 5/8 | 190.5 | 8 |

| 5 | 254 | 23.9 | 185.7 | 8 | 22.4 | 3/4 | 215.9 | 9 |

| 6 | 279.4 | 25.4 | 215.9 | 8 | 22.4 | 3/4 | 241.3 | 12 |

| 8 | 342.9 | 28.4 | 269.7 | 8 | 22.4 | 3/4 | 298.5 | 20 |

| 10 | 406.4 | 30.2 | 323.9 | 12 | 25.4 | 7/8 | 362 | 32 |

| 12 | 482.6 | 31.8 | 381 | 12 | 25.4 | 7/8 | 431.8 | 50 |

| 14 | 533.4 | 35.1 | 412.8 | 12 | 28.4 | 1 | 476.3 | 64 |

| 16 | 596.9 | 36.6 | 469.9 | 16 | 28.4 | 1 | 539.8 | 82 |

| 18 | 635 | 39.6 | 533.4 | 16 | 31.8 | 1-1/8 | 577.9 | 100 |

| 20 | 698.5 | 42.9 | 584.2 | 20 | 31.8 | 1-1/8 | 635 | 129 |

| 24 | 812.8 | 47.8 | 692.2 | 20 | 35.1 | 1-1/4 | 749.3 | 195 |

A blind flange, also known as a blank flange, is a type of flange that is used to close the end of a pipe or vessel. It is a solid disk with no opening or bore in the center. Blind flanges are typically used for the following purposes:

1. Closure: When a section of the pipeline needs to be closed off temporarily or permanently, a blind flange is installed at the end to seal it completely. This helps prevent flow through the pipe and ensures the integrity of the system.

2. Inspection and Testing: Blind flanges are often used during pressure testing, leak testing, or visual inspection of the piping system. They provide a solid barrier that allows for safe and controlled testing without any fluid leakage.

3. Future Expansion: In situations where additional sections of piping may be added in the future, a blind flange can be used as a temporary closure until the expansion occurs. It provides a convenient and secure way to close off the end of the pipe until it is ready for connection.

4. Aesthetics and Safety: Blind flanges can be used for aesthetic purposes in situations where the end of a pipe needs to be covered or concealed. They also provide a safety measure by capping off unused or open ends of pipes, eliminating the risk of accidental entry or injury.

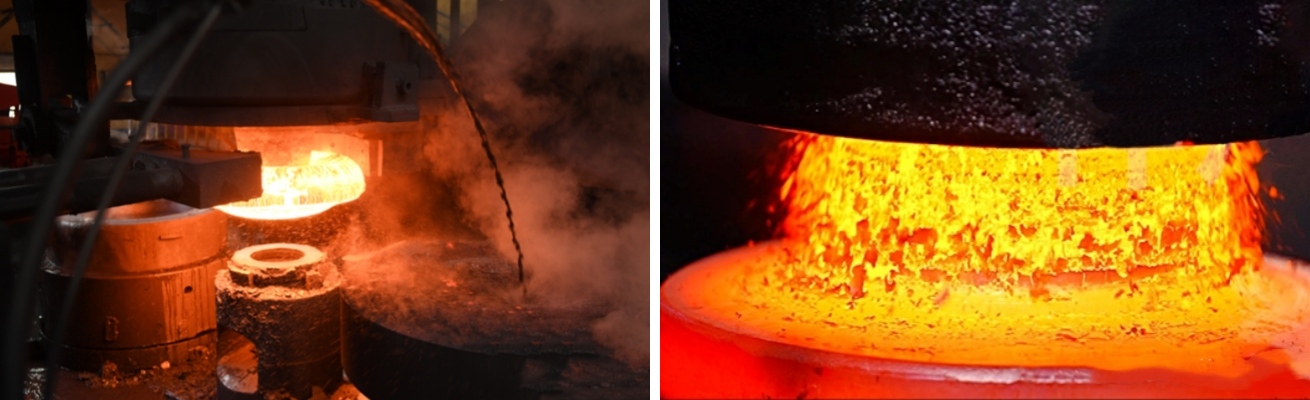

The company has equipped facilities for manufacturing. Now it has five forging machines, one of which is forging machine whose capacity reaches 3600-ton, one is numerical control ring roll whose capacity reaches 6300 mm (Diameter), one is 1.5 ton hammers and the other two are 1-ton air hammers. There are 7 gas generators used for forge heating, 16 industrial resistance furnaces for heat treatment and more than 80 metal processing equipment among which there is a numeric control Standing Lathe whose processing diameter can reach 5meters. The company has an annual production capacity of 50,000 tons of middle and high-pressure flanges and various steel forgings for boilers and pressure vessels. The maximum pressure of manufactured flanges can reach 2500Lb, the maximum diameter can reach about 6 meters and the maximum weight of unit forging can reach 30 tons.

Wuxi Changrun uses plastic protective covers to protect the flange sealing surface, and then uses waterproof plywood boxes for packaging. Waterproof wooden box packaging is suitable for sea transportation.

Material:

| Carbon Steel |

ASTM A105, ASTM A350 LF1, ASTM A350 LF2, S235JR, P245GH, P250GH, P280GH, ASTM A694 F42, ASTM A694 F46, ASTM A694 F52, ASTM A694 F56, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70, etc |

| Stainless Steel |

ASTM A182 F304, ASTM A182 F304L, ASTM A182 F304H, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F317, ASTM A182 F317L, ASTM A182 F321, ASTM A182 F310, ASTM A182 F347, etc. |

| Alloy Steel |

ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, etc. |

| Duplex and super duplex steel |

ASTM A815 UNS S31803, ASTM A815 UNS S32205, ASTM A815 UNS S32750, ASTM A815 UNS S32760 |

Specification:

Size Range: DN15-DN2000, 1/2 Inch-80 Inch

Face Finish: RF, FF, RTJ, TF, GF

Standard & Pressure Ratings:

1. ANSI/ASME/ASTM B16.5/B16,47: 150 LB, 300 LB, 400 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

2. DIN/UNI: PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, PN250, PN320

Service:

Surface Treatment: Black painting, anti-rust varnish, anti-rust oil, hot-galvanized

Non-destructive Testing: penetration test, ultrasonic test, radiographic test

Certificate: CE, ISO, PED, TS, BV, CQC Certificate

Packing: Plywood Case or Pallet