What Are You Looking For?

Forged Lap Joint Flange (LJ Flange) Manufacturer Changrun Supplies Forged LJ Flanges,

DN32 (1-1/4 Inch),

300 LB (PN50).

Flange face: RF

Material: ASTM A182 F316, ASTM A182 F316L.

Certificates: CE, ISO, PED, TS, BV, CQC.

A lap joint flange (LJ) is an assembly of two elements involving a stub end and a lap joint ring flange (also called a ‘lap joint flange’). To be technically correct, the stub end is not part of a lap joint flange. However, a lap joint flange is always used in conjunction with a stub end, so both parts are often collectively referred to as a ‘lap joint flange’.

ASME B16.5 Class 300 RF

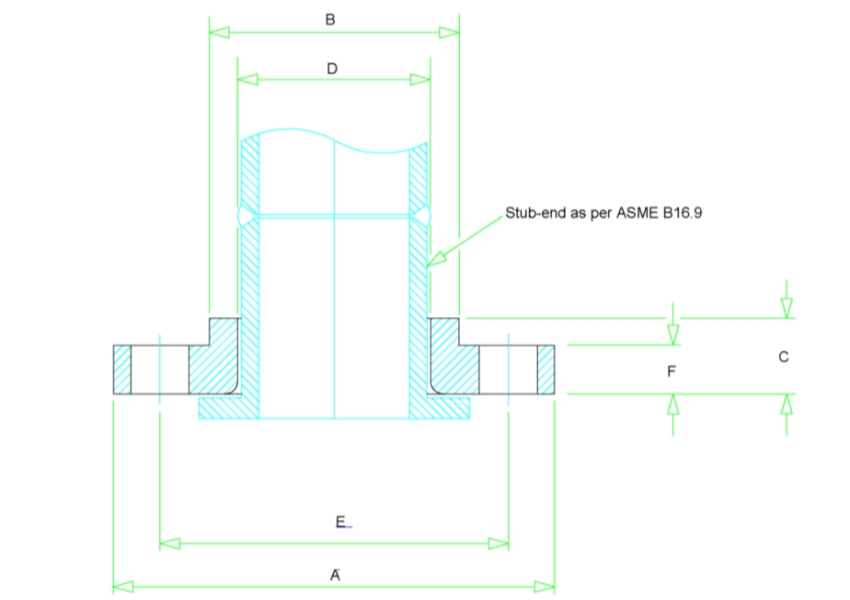

Lap Joint Flange Dimension

A lap joint flange, also known as a loose flange, is a type of flange that is used to connect two separate sections of pipe or fittings together. It consists of two main components: the stub end and the backing flange.

During installation, the stub end is slid onto the pipe or fitting, and the backing flange is aligned with the stub end. The two components are then fastened together using bolts, which are inserted through the bolt holes in the backing flange and tightened. The lap joint allows for rotational movement and adjustment between the two components, providing flexibility in alignment and ease of assembly.

One of the advantages of the lap joint flange is its ability to handle misalignments and adjustments during installation. The rotational movement provided by the lap joint allows for slight angular deviations or changes in the centerline alignment of the pipes or fittings. This makes the lap joint flange suitable for applications where alignment precision is not critical or where there may be thermal expansion or vibration.

Specification:

Size Range: DN15-DN2000, 1/2 Inch-80 Inch

Face Finish: RF, FF, RTJ, TF, GF

Standard & Pressure Ratings:

1. ANSI/ASME/ASTM B16.5/B16,47: 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

2. DIN/UNI: PN6, PN10, PN16, PN25, PN40, PN64

Material:

A. Carbon Steel: ASTM A105, ASTM A350 LF1, ASTM A350 LF2, S235JR, P245GH, P250GH, P280GH, ASTM A694 F42, ASTM A694 F46, ASTM A694 F52, ASTM A694 F56, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70, etc

B. Stainless Steel: ASTM A182 F304, ASTM A182 F304L, ASTM A182 F304H, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F317, ASTM A182 F317L, ASTM A182 F321, ASTM A182 F310, ASTM A182 F347, etc.

C. Alloy Steel: ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, etc.

D. Duplex and super duplex steel: ASTM A815 UNS S31803, ASTM A815 UNS S32205, ASTM A815 UNS S32750, ASTM A815 UNS S32760

Service:

Surface Treatment: Black painting, anti-rust varnish, anti-rust oil, hot-galvanized

Non-destructive Testing: penetration test, ultrasonic test, radiographic test

Certificate: CE, ISO, PED, TS, BV, CQC Certificate

Packing: Plywood Case or Pallet