What Are You Looking For?

Manufacturer Changrun Supply SPADE RING BLIND FLANGE ( PADDLE BLIND, SINGLE BLIND, BLANKING SPADE), DN15-DN2000 (1/2-80 Inch), 150-2500 LB (PN6-PN420). Flange face: RF, FF, RTJ. Material: ASTM A694 F56. Certificates: CE, ISO, PED, TS, BV, CQC.

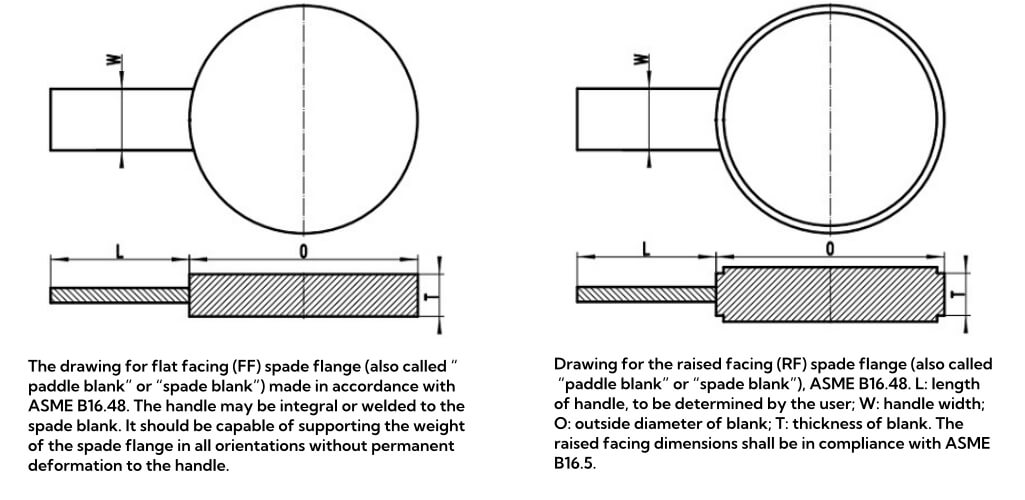

Dimensions of Spades Blind Flange/ paddle blanks/ spade flanges

ASME B16.48 Class 300 RF

| NPS | O | T | W | Weight |

|---|---|---|---|---|

| 1/2 | 51 | 6.4 | 38 | 0.14 |

| 3/4 | 64 | 6.4 | 38 | 0.21 |

| 1 | 70 | 6.4 | 38 | 0.26 |

| 1-1/4 | 79 | 6.4 | 38 | 0.34 |

| 1-1/2 | 92 | 6.4 | 38 | 0.46 |

| 2 | 108 | 9.7 | 51 | 0.89 |

| 2-1/2 | 127 | 9.7 | 51 | 1.22 |

| 3 | 146 | 9.7 | 64 | 1.65 |

| 3-1/2 | 162 | 12.7 | 64 | 2.51 |

| 4 | 178 | 12.7 | 64 | 3.04 |

| 5 | 213 | 15.7 | 76 | 5.18 |

| 6 | 248 | 15.7 | 76 | 6.98 |

| 8 | 305 | 22.4 | 76 | 14.45 |

| 10 | 359 | 25.4 | 102 | 22.52 |

| 12 | 419 | 28.4 | 102 | 33.96 |

| 14 | 483 | 31.8 | 108 | 49.54 |

| 16 | 536 | 38.1 | 108 | 72.38 |

| 18 | 594 | 41.1 | 114 | 95.70 |

| 20 | 651 | 44.5 | 121 | 123.74 |

| 24 | 772 | 50.8 | 140 | 197.18 |

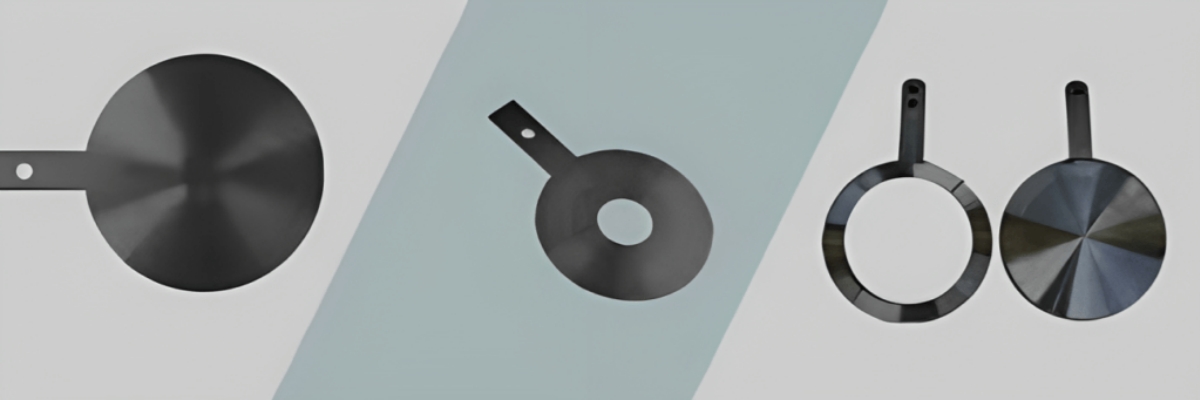

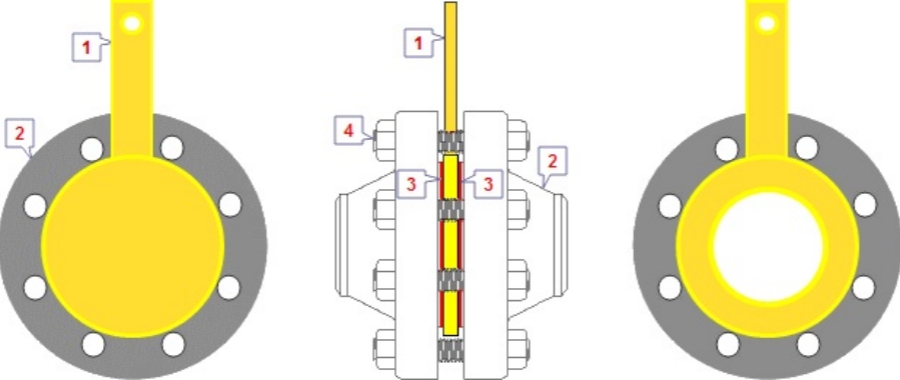

A paddle blind flange, also known as spade blind flange or line blind, is a special type of flange used in piping systems for temporary or permanent isolation of a section of the pipeline. It consists of a solid disk or paddle-shaped plate that is inserted between two standard flanges, typically of the same size and rating.

The paddle flange acts as solid barrier to block the flow fluids or gases in pipeline. It is commonly used in situations where maintenance or repair work needs to be carried out on a specific section of the pipeline, or when a section of the pipeline is no longer in use and needs to be isolated.

The design of the paddle blind flange allows for easy installation and removal without disturbing the rest of the pipeline. It is inserted between the two flanges and secured using the same bolts and nuts that are used to connect the flanges. The solid disk of the paddle blind seals off the pipeline, preventing any flow through the isolated section.

Specification:

Size Range: DN15-DN2000, 1/2 Inch-80 Inch

Face Finish: RF, FF, RTJ, TF, GF

Standard & Pressure Ratings:

1. ANSI/ASME/ASTM B16.5/B16,47: 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

2. DIN/UNI: PN6, PN10, PN16, PN25, PN40, PN64

3. ANSI B16.5, ANSI B16.47, ANSI B16.48, ANSI B16.36, BS4504, EN1092, UNI 2277/2278, DIN, JIS, GOST-12820

Material:

A. Carbon Steel: ASTM A105, ASTM A350 LF1, ASTM A350 LF2, S235JR, P245GH, P250GH, P280GH, ASTM A694 F42, ASTM A694 F46, ASTM A694 F52, ASTM A694 F56, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70, etc

B. Stainless Steel: ASTM A182 F304, ASTM A182 F304L, ASTM A182 F304H, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F317, ASTM A182 F317L, ASTM A182 F321, ASTM A182 F310, ASTM A182 F347, etc.

C. Alloy Steel: ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, etc.

D. Duplex and super duplex steel: ASTM A815 UNS S31803, ASTM A815 UNS S32205, ASTM A815 UNS S32750, ASTM A815 UNS S32760

Service:

Surface Treatment: Black painting, anti-rust varnish, anti-rust oil, hot-galvanized

Non-destructive Testing: penetration test, ultrasonic test, radiographic test

Certificate: CE, ISO, PED, TS, BV, CQC Certificate

Packing: Plywood Case or Pallet