What Are You Looking For?

Pipe Fitting Manufacturer Changrun Supplies Concentric Reducer and Eccentric Reducer,

Type: Conc Reducer

Size: DN200xDN100 ( 8 x 4 Inch)

Wall Thickness: SCH 40.

Material: ASTM A 234 WPB

Standard: ANSI B16.9.

End Connection: Butt Weld

Certificates: CE, ISO, PED, TS, BV, CQC.

Butt Weld Reducers

Concentric and Eccentric ASME B16.9

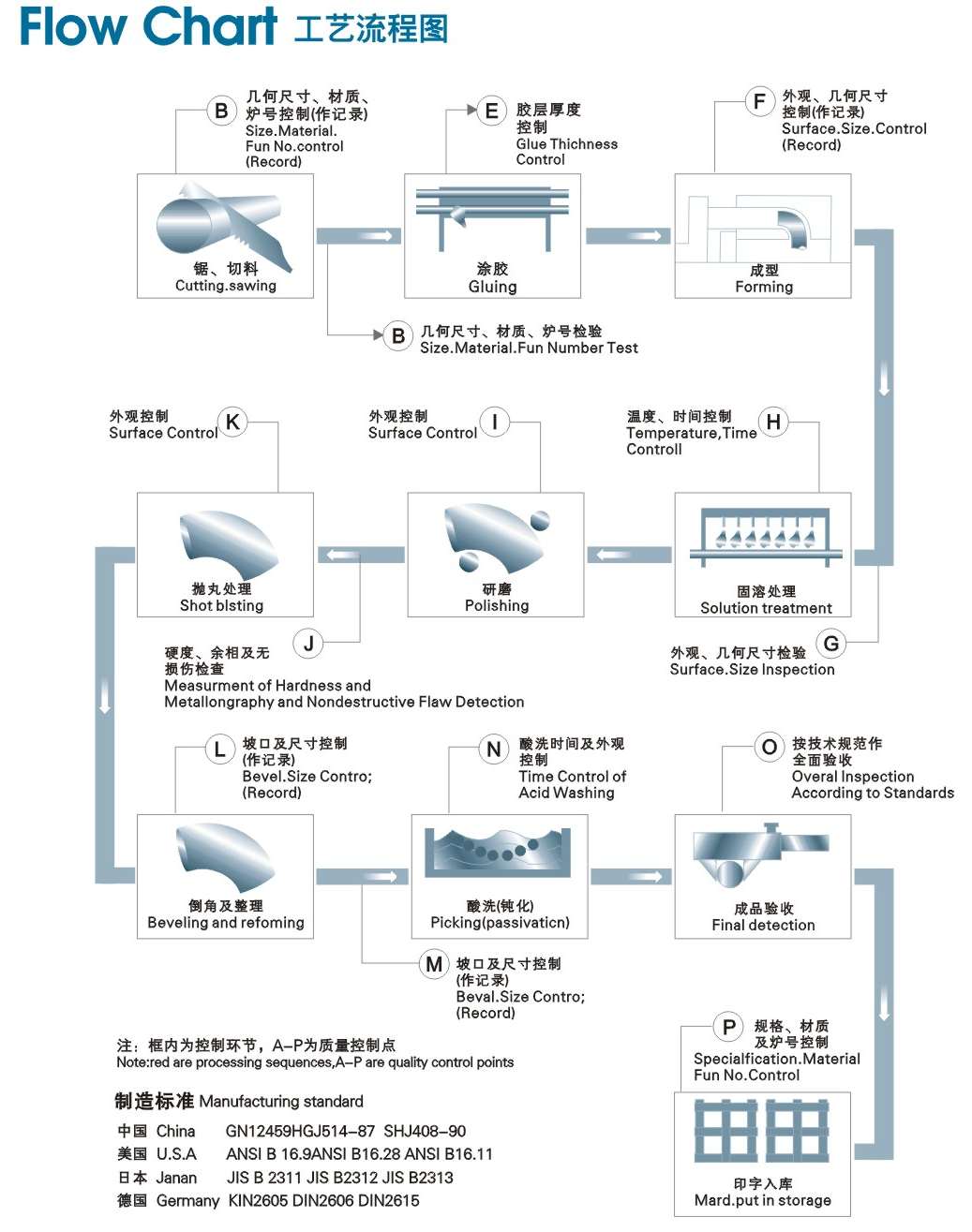

Pipe fitting production process

Pipe reducers are available in a wide range of materials, including carbon steel, stainless steel, alloy steel, and various plastic materials depending on the temperature, pressure, and compatibility requirements of the application.

In summary, a pipe reducer is a fitting used to join pipes of different sizes in a piping system. It allows for a smooth transition between pipes, maintaining flow efficiency and preventing turbulence. Concentric reducers provide a uniform reduction in pipe size, while eccentric reducers are used to offset the centerlines of the connected pipes.

Specification:

| Elbow Degree |

45, 90, 180 Deg. Long/Short Radius Elbows |

| Size Range |

Carbon Steel: 1/2”-96” Stainless Steel: 1/2” – 24” (Seamless and ERW), 26” – 72” (Welded) |

| Schedule |

SCH5S, 10S, 40S, STD, 80S, XS, XXS, SCH10-SCH160 |

| Pressure Ratings |

Threaded fittings: 2000lbs, 3000lbs, 6000lbs. Socket-weld fittings: 3000lbs, 6000lbs, 9000lbs. |

| Pipe Fitting Standard |

ANSI B16.9, ANSI B16.28, DIN 2605, DIN2615, DIN2616, JIS B2312, JIS B2313, ANSI/ASME B16.11, MSS SP-43, SP-79, SP-83, SP-95-, SP-97, BS3799, JIS B2316 |

Pipe Fitting Material:

| Carbon Steel |

ASTM A 234 WPB, A420 WPL1, WPL3, WPL6, ASTM A860 WPHY 42, WPHY52, WPHY60, WPHY65, WPHY70 |

| Stainless Steel |

ASTM A403 WP304/304L, WP316/316L, WP321, WP347 |

| Alloy Steel |

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91 |

| Duplex & Super Duplex Steel |

ASTM A815 UNS S31803, UNS S32750, UNS S32760 |

| Nickel & Nickel Alloy |

Nickel 200, Nickel 201, Monel 400, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36 Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, |

| Titanium & Titanium Alloy |

ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12, ASTM B381 F1, F2, F7, F12 |

Service:

| Surface Treatment |

Black painting, anti-rust varnish, anti-rust oil, hot-galvanized |

| Non-destructive Testing |

penetration test (PT), ultrasonic test (UT), radiographic test(RT) |

| Certificate |

CE, ISO, PED, TS, BV, CQC Certificates |

| Packing |

Plywood Case or Pallet |