What Are You Looking For?

Fixed tube sheet heat exchanger refers to a type of tube and shell heat exchanger in which the tube sheets at both ends of the tube bundle are fixedly connected to the shell by welding. After welding the tube sheet and shell, it can also serve as a flange and be connected to channel flange with bolts. The advantage is that it has a simple structure and requires the smallest inner diameter of the shell under the condition of equal heat transfer surfaces. The disadvantage is that it will generate significant thermal stress when the temperature difference between the shell side and the tube side medium is large, it can cause the joint between the tube and the tube sheet to pull off and rupture, resulting in leakage or instability of the tube. At the same time, maintenance and shell side cleaning are also inconvenient, and are widely used in general situations, but are also limited by temperature differences.

Structural Principles

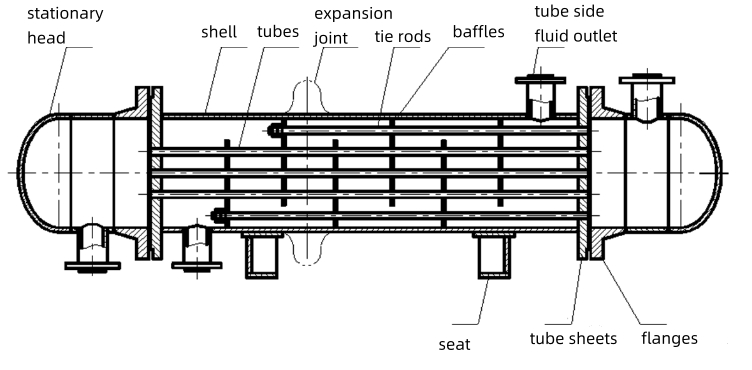

The working principle of a fixed tube plate heat exchanger is that fluids of different temperatures flow into the tube side and shell side, and heat exchange is completed through heat exchange. When the temperature difference between two fluids is large, in order to avoid higher temperature difference stress, a compensation ring (expansion joint) is usually added at an appropriate position on the shell side. When the thermal expansion of the shell and tube bundle is different, the expansion joint undergoes slow elastic deformation to compensate for the thermal expansion caused by temperature difference stress.

Structure

A fixed tube sheet heat exchanger consists of components such as a channel, shell, tube sheet, and tube. It has a compact structure with more tubes and a larger area under the same diameter, making it easier to manufacture.

The structural feature of a fixed tube sheet heat exchanger is that a tube bundle is installed in the shell, and the tubes are fixed to the tube sheet at both ends by welding or expanding. The two end tube sheets are directly welded to the shell, the inlet and outlet tubes of the shell side are directly welded to the shell, the tube sheets and the cover flange are fastened with bolts, and the inlet and outlet tubes of the tube side are directly welded to the cap. Several baffle plates are set up in the tube bundle according to the length of the heat exchange tubes. This type of heat exchanger can be divided into any number of passes using pass partition.

Characteristic

The fixed tube sheet heat exchanger has a simple structure, low manufacturing cost, convenient cleaning of the tube side, and can be divided into multiple passes for the tube side or double passes for the shell side. It has a wide range of specifications and is widely used in engineering. Shell side cleaning is difficult and should not be used for dirty or corrosive media. When the difference in expansion is large, an expansion joint can be installed on the shell to reduce the thermal stress caused by the temperature difference between the tube and shell.

The characteristics of fixed tube sheet heat exchangers are:

1. The bypass seepage is relatively small;

2. Less use of forgings, low cost;

3. No internal leakage;

4. The heat transfer area is 20% to 30% larger than that of a floating head heat exchanger.

The disadvantages of fixed tube sheet heat exchangers are:

1. The temperature difference between the shell and the pipe wall is large. When t ≥ 50 ℃, an expansion joint must be installed on the shell;

2. Easy to generate temperature difference force, and damage can occur due to temperature difference stress between the tube sheet and the tube end;

3. The shell cannot be mechanically cleaned;

4. If the pipes are corroded, the shell must also be discarded, resulting in a lower lifespan of the equipment.

Wuxi Changrun is a manufacturer of all kinds of steel Flanges, tube sheets, tubes, act., All the tube sheets are made according to client’s requirement.