What Are You Looking For?

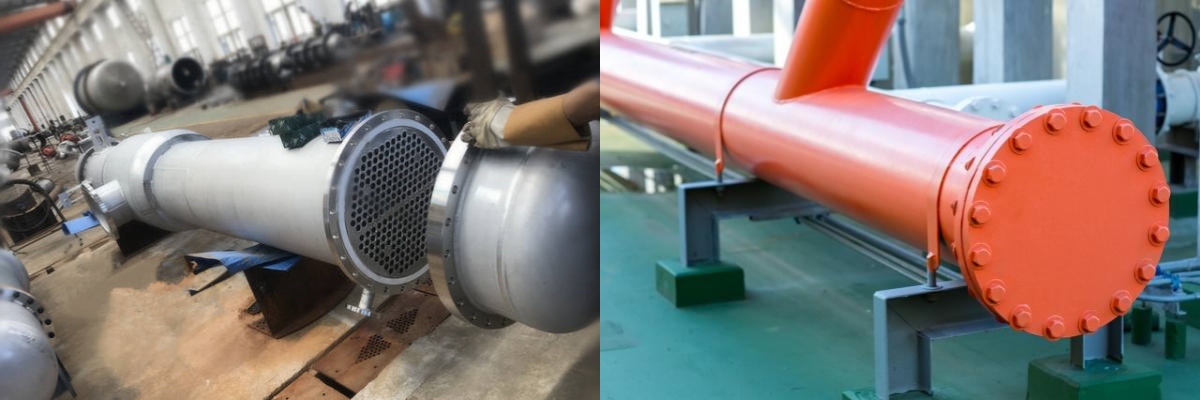

Titanium, due to its excellent corrosion resistance, is widely used as a material for various chemical reaction vessels and heat exchangers, and has been widely applied in fields such as petrochemicals, salt production, power, seawater desalination, and marine engineering. However, titanium has a drawback, which is that it is difficult to process and results in higher costs, especially when used as structural components. The effective solution that people have come up with currently is to use titanium steel composite plates. Titanium steel composite plates can also be used to produce titanium clad steel tube sheets.

What is Titanium Clad Steel Plate?

Titanium steel composite plate refers to a metal composite plate coated with corrosion-resistant titanium metal on the surface of ordinary steel plates. Titanium steel composite plates have both the strength of ordinary steel plates as structures and the corrosion resistance of titanium metal. The most important thing is that the cost has been greatly reduced, so they are widely used in various fields.

From the production situation of domestic and international titanium steel composite plates, there are currently three main manufacturing methods for titanium steel composite plates: explosive bonding method, thick plate rolling method, and continuous hot rolling method. The titanium steel composite plate produced by explosive bonding method and thick plate rolling method is a thick plate, mainly used as a corrosion-resistant structural material. The titanium steel composite plate manufactured by continuous hot rolling is a thin plate, mainly used in marine civil engineering.

Application fields of titanium steel clad plates

1. Manufacturing of petrochemical and chemical container equipment

The manufacturing of petrochemical and chemical container equipment is a traditional application field of titanium steel composite plate materials, and its application volume has always been at the forefront. Titanium has good stability in various acid, alkali, and salt media in the chemical industry, and titanium steel composite plates have also been able to play an irreplaceable role in petroleum refining and chemical plants.

Titanium also has special corrosion resistance to bleaching agents such as chlorine dioxide, chlorite, and chlorite. Therefore, titanium steel composite plates also have important applications in bleaching equipment in the textile, printing, and dyeing industries, as well as the papermaking industry.

2. Manufacturing of vacuum salt making equipment

Titanium and its alloys have excellent resistance to seawater, chloride solution corrosion, and fluid erosion. The evaporation chamber made of titanium steel composite plate has good effects on slowing down corrosion, preventing salt scaling on the evaporation tank wall, prolonging production cycle, and improving salt quality, greatly reducing the operating cost of salt plant equipment.

3. Seawater desalination field

Titanium and its alloys have excellent resistance to seawater, chloride solution corrosion, and fluid erosion, and titanium is non-toxic and harmless, making titanium steel composite plates an ideal material for seawater desalination equipment.

4. Nuclear power equipment manufacturing

Thick composite layer (composite layer ≥ 8mm) and large plate width (single sheet area ≥ 20m) titanium steel composite plate are the main materials used for condenser tube plates in nuclear power equipment, and there is a high demand for them, with very broad application prospects.

In summary, titanium steel composite plates have excellent corrosion resistance and strength, making them an ideal material for manufacturing equipment in corrosion-resistant environments. With the continuous improvement of the production process of titanium steel composite plates, the application of titanium steel composite plates will also become more widespread and widespread.