What Are You Looking For?

Pressure rating of flanges

A flange is a component that connects shafts and is used for connecting pipe ends; It is also used for equipment inlet and outlet, for connecting two devices, like the gearbox flange. A flange connection or flange joint refers to a detachable connection formed by a combination of flanges, gaskets, and bolts connected together as a sealing structure. Pipeline flange refers to the flange used for piping in pipeline equipment, and when used on equipment, it refers to the inlet and outlet flanges of the equipment. According to the different nominal pressure ratings of valves, flanges with different pressure ratings are configured in pipeline flanges. Several commonly used flange pressure ratings are classified according to international standards:

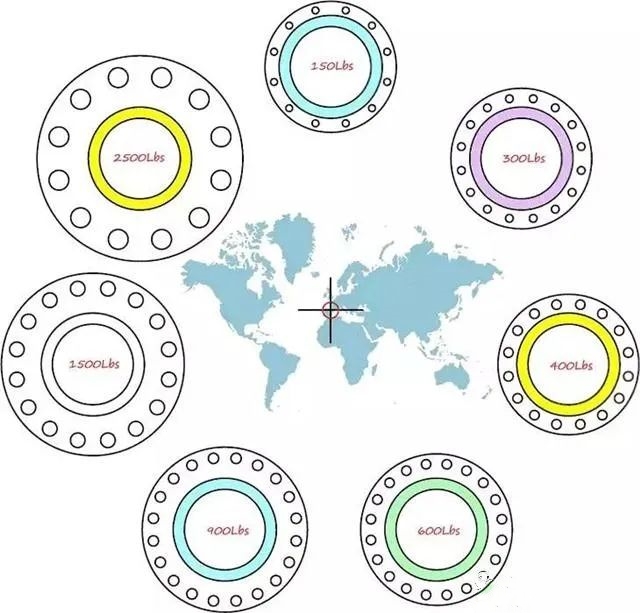

According to ASME B16.5, steel flanges have 7 pressure ratings: Class150-300-400-600-900-1500-2500 (corresponding to Chinese standard flanges with PN0.6, PN1.0, PN1.6, PN2.5, PN4.0, PN6.4, PN10, PN16, PN25, PN32Mpa ratings)

The pressure rating of the flange is very clear. Class300 flanges can withstand greater pressure than Class150, because Class300 flanges need to be made of more materials to withstand greater pressure. However, the compressive capacity of flanges is influenced by multiple factors. The pressure rating of a flange is expressed in pounds, and there are different ways to represent a pressure rating. For example, the meanings of 150Lb, 150Lbs, 150 #, and Class150 are the same.

Example of pressure level

The pressure bearing capacity of flanges varies with different temperatures. As the temperature rises, the pressure bearing capacity of the flange decreases. For example, the Class150 flange has a pressure capacity of 270PSIG at room temperature, 180 PSIG at 400 ℉, 150 PSIG at 600 ℉, and 75 PSIG at 800 ℉.

In other words, when the pressure drops, the temperature is allowed to rise, and vice versa. Due to the fact that flanges can be manufactured from different materials, such as stainless steel, cast iron, ductile iron, carbon steel, etc., each material has a different pressure rating.

The following figure is an example of an NPS12 (DN300) flange. As you can see, the diameter of the flange inner hole and raised surface are the same. However, the outer diameter of the flange, the diameter of the bolt hole center circle, and the diameter of the bolt hole increase with the increase of pressure level.

The number and diameter of bolt holes are:

CL 150-12 x 25.4; CL 300-16 x 28.6; CL 400-16 x 34.9; CL 600-20 x 34.9; CL 900-20 x 38.1; CL 1500-16 x 54; CL 2500-12 x 73

Pressure and Temperature Rating - Example

Pressure temperature rating refers to the allowable working gauge pressure (pressure unit in Bar) of a material and grade at the rated temperature (degrees Celsius). For intermediate temperatures, linear insertion method is allowed to determine. However, insertion between flange levels is not allowed. If the bolts and gaskets of the flange joint meet the relevant limiting conditions, and the alignment and assembly of the flange joint comply with good regulations, then such a flange joint can be suitable for the rated pressure temperature value. If the latter is used for flange joints that do not meet these limiting conditions, the user is responsible.

The rated temperature corresponding to the rated pressure refers to the shell temperature of the pressure vessel for flanges and flange fittings. In general, this temperature is the same as the temperature of the stored fluid. The responsibility for selecting pressure ratings based on the temperature of the stored fluid is borne by the user. When the temperature is below -29 ℃ (-20 ℉), the rated value should not exceed the rated value at -29 ℃ (-20 ℉).