What Are You Looking For?

What is a flange?

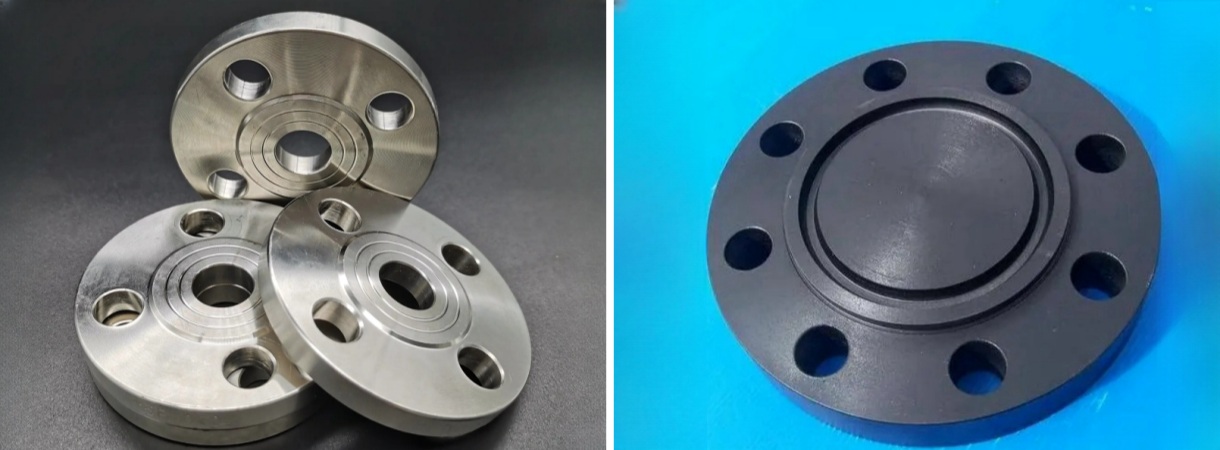

A flange is mainly used for connecting parts between pipelines and valves, between pipelines, and between pipelines and equipment, which play a sealing role. Because there are many applications between these equipment and pipelines, two planes are connected by bolts, and the connecting parts with sealing function are all called flanges. Generally, flanges have circular holes for fixing purposes. For example, when used at pipeline connections, a sealing ring is added between two flange plates, and then bolted together. flanges with different pressures have different thicknesses and use different bolts. The main materials used for flanges are carbon steel, stainless steel, and alloy steel, etc.

The difference between stainless steel flange and carbon steel flange

Both stainless steel and carbon steel belong to the category of steel, but they are fundamentally different because they contain different other elements. Generally, steel that only contains carbon is called carbon steel, while stainless steel contains other alloy materials, and its corrosion resistance and wear resistance are very good. The main differences between the two are as follows:

1. Density difference: The density of carbon steel is slightly higher than that of ferritic and martensitic stainless steel, and slightly lower than that of austenitic stainless steel.

2. Different compositions: Stainless steel is the abbreviation of stainless and acid resistant steel. Steel that is resistant to weak corrosive media such as air, steam, water, or has rust resistance is called stainless steel; And the type of steel that is resistant to chemical corrosion media (such as acid, alkali, salt, etc.) is called acid resistant steel. Carbon steel is an iron carbon alloy with a carbon content ranging from 0.0218% to 2.11%. Also known as carbon steel. Generally, it also contains small amounts of silicon, manganese, sulfur, and phosphorus.

3. Different corrosion resistance. Carbon steel flanges are prone to oxidation and corrosion, and are not corrosion-resistant; Stainless steel flanges have better corrosion resistance due to their high proportion of elements such as chromium and nickel.

4. Different high temperature resistance performance. Carbon steel flanges are prone to failure in high temperature environments; Stainless steel flanges can effectively resist thermal expansion and deformation at high temperatures.

5. Different resistances: The resistivity increases in order of carbon steel, ferrite, martensite, and austenitic stainless steel.

6. Different coefficients of expansion: The order of linear coefficients of expansion is also similar, with austenitic stainless steel having the highest coefficient and carbon steel having the lowest.

7. Magnetic differences: Carbon steel, ferritic and martensitic stainless steel have magnetism, while austenitic stainless steel has no magnetism. However, when it undergoes martensitic transformation during cold work hardening, magnetism will be generated. Heat treatment can be used to eliminate this martensitic structure and restore its non-magnetism.

Advantages and disadvantages of carbon steel and stainless steel flanges

Carbon steel flanges are relatively inexpensive and have high tensile strength, making them commonly used in some low-pressure situations. However, carbon steel flanges have poor corrosion resistance and are prone to rusting in humid or acidic environments.

Stainless steel flanges are relatively expensive, but they have good corrosion resistance and can maintain stable performance in high-temperature and high-pressure environments. However, the tensile strength of stainless steel flanges is weak and needs to be selected according to specific usage scenarios.

The use of carbon steel and stainless steel flanges

Carbon steel flanges are suitable for general low-pressure water, gas, and oil pipelines and are an economical choice. However, regular maintenance is required during use to prevent rusting.

Stainless steel flanges are suitable for high temperature and high pressure applications, such as chemical, petroleum, pharmaceutical, and food industries. Stainless steel flanges can withstand high pressure and temperature, and have corrosion resistance, which can maintain their original performance for a long time.

When choosing carbon steel or stainless steel flanges, it is necessary to choose according to the specific usage environment and requirements. In general low-pressure situations, carbon steel flanges can be chosen as an economical option, but regular maintenance is required. In high-temperature and high-pressure production environments, it is necessary to choose stainless steel flanges with good corrosion resistance to ensure the normal operation of the product.