What Are You Looking For?

1. Analysis of corrosion causes

A. Electrochemical corrosion

There are different defects in the shape of the weld between the tube sheet and the tubes, such as uneven distribution of weld stress, slag inclusions, pores, dents, etc.. When in use, the tube sheet part generally comes into contact with industrial cooling water, and impurities, microorganismssalts, salt and gases in industrial cooling water can cause corrosion to the tube sheets and welds. This is electrochemical corrosion.

Research has shown that industrial water, whether fresh or seawater. Contains various ions and dissolved oxygen, among which the concentration changes of chloride ions and oxygen play an important role in the corrosion shape of metals. In addition, the complexity of the metal structure can also affect the corrosion morphology. Therefore, the corrosion of the welds between the tube sheet and the tube is mainly caused by corrosion of the holes and gaps.

From the outside, there will be many corrosion products and sediments on the surface of the tube plate, distributed with pits of varying sizes. When using seawater as a medium, galvanic corrosion may also occur.

B. Chemical corrosion

Chemical corrosion is the corrosion of the medium, and when the heat exchanger tube plate comes into contact with various chemical media, it will be corroded by the chemical media. In addition, the heat exchanger tube sheet will also produce some bimetallic corrosion between the heat exchanger tubes, some tube sheets are still subjected to long-term erosion by corrosive media. Especially for fixed tube sheet heat exchangers, there is also thermal stress. And the connection between the tube sheet and the heat exchange tube is prone to leakage, leading to the failure of the heat exchanger.

In conclusion, the main factors affecting the corrosion of heat exchanger tube sheets are:

(1)Medium composition and concentration

The impact of concentration is inconsistent. For example, in hydrochloric acid, the higher the concentration, the more severe the corrosion. Carbon steel and stainless steel are most severely corroded in sulfuric acid with a concentration of about 50%, and when the concentration increases to over 60%, the corrosion actually sharply decreases.

(2)Impurities

Harmful impurities include sulfur ions, chloride ions, ammonia ions, cyanide ions, etc. These impurities can cause serious corrosion in some cases.

(3)Temperature

Corrosion is a chemical reaction, and for every 10 ℃ increase in temperature, the corrosion rate increases by about 1-3 times, but there are exceptions.

(4)PH value

Generally, the smaller the pH value, the greater the corrosion of the metal.

(5)Flow rate

In most cases, the higher the flow rate, the greater the corrosion.

2, Analysis of the advantages of polymer composite material technology application

Polymer composite materials are high-tech disciplines developed on the basis of organic chemistry, polymer chemistry, material mechanics and colloid chemistry. They use polymer penetration to form intermolecular forces, forming van der Waals forces and hydrogen bonds with repair components to ensure their adhesion performance with repair and protection components. By utilizing polymer penetration to form intermolecular forces, it forms van der Waals forces and hydrogen bonds with the repaired components, thereby ensuring its adhesive performance with the repaired protective components.

The special molecular structure of polymer composite materials endows them with the ability to adapt to alternating deformation and temperature changes, ensuring that the material has excellent wear resistance, cavitation resistance and anti-corrosion. Its high-density molecular weight and smooth surface coating can improve the efficiency of vacuum pump use. Polymer composite materials are non-toxic, non volatile, and harmless, and can come into direct contact with the skin.

The use of polymer composite repair materials for surface organic coating anti-corrosion is currently one of the effective anti-corrosion measures. Polymer composite materials can form a solidified protective coating on the protected substrate and play a shielding role, separating the substrate steel plate from circulating water to prevent corrosion and corrosion; The anti permeability performance, stability to corrosive media, strong adhesion, and corresponding mechanical properties of coatings ensure the application effect of protective coatings and the operating cycle of equipment.

Case 1: Anti-corrosion and anti-rust protection of tube sheets and water chambers of waste heat power generation condenser

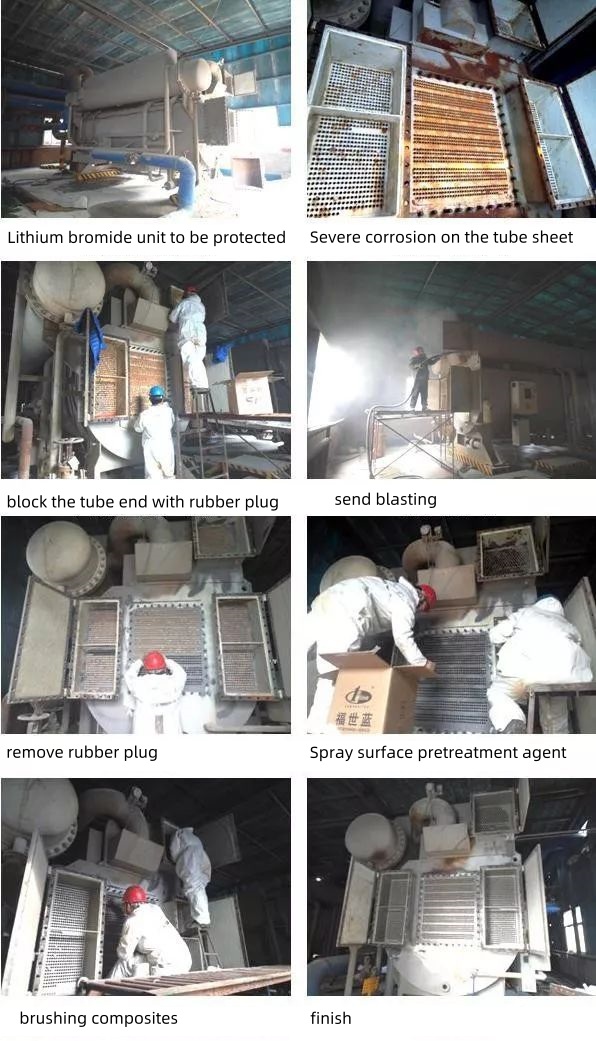

Case 2: Anti-corrosion protection of condenser tube sheets of lithium bromide absorption refrigerator

Case 3: Tube plate corrosion protection of tube heat exchanger (methane chloride)