What Are You Looking For?

Forged Tube Sheets Manufacturer Changrun Supplies Forged Tubesheet.

Material: Inconel 625

Dimension: 400mm X 400mm X 10mm,

Hole diameter:10mm

Lagest Forging: 100MT.

Max OD of tube sheets: 8 Meters.

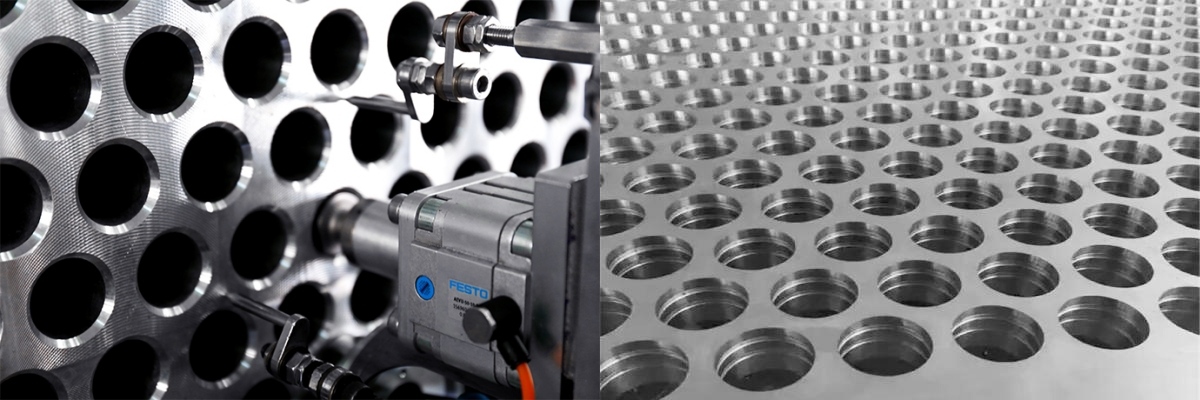

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

Tube sheet products are widely used in industries such as seawater desalination, heat exchangers, pressure vessels, paper machines, petroleum smelting, steam turbines, nuclear power, etc. Wuxi Changrun has been committed to deep processing of tube plates since its establishment. After years of development, combined with the "one-stop" service concept of integrating steel materials and processing, it has created a unique service platform for tube sheet and baffle plate processing.

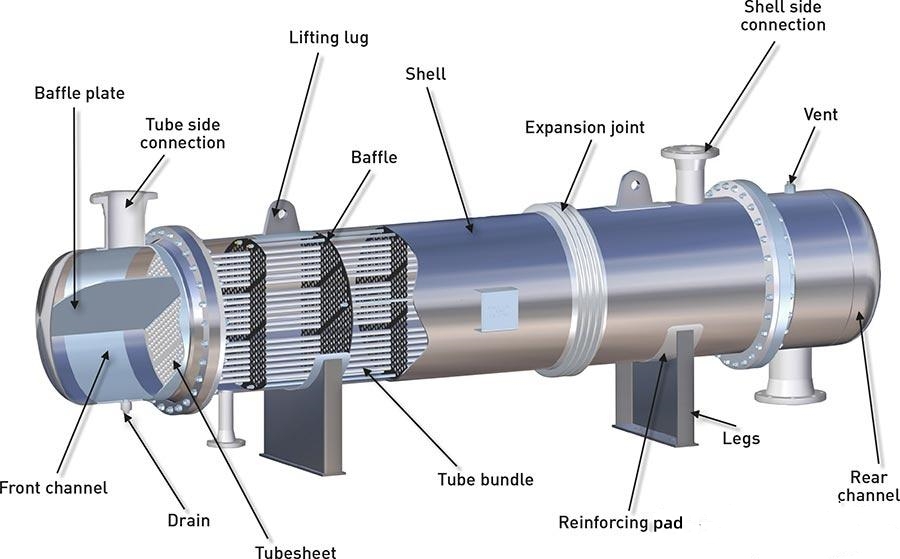

Tube sheets are extensively used in heat exchangers to connect and support heat exchange tubes. They enable the transfer and exchange of heat energy between different fluid streams, such as in oil refineries and chemical plants. Tube sheets also serve as a crucial element in maintaining the separation between different fluid streams within the heat exchanger. They create a barrier between the tubes carrying one fluid and the surrounding shell or chamber carrying another fluid. This separation is vital in applications where it is essential to prevent mixing or contamination of the fluids, such as in chemical processing or food industries.

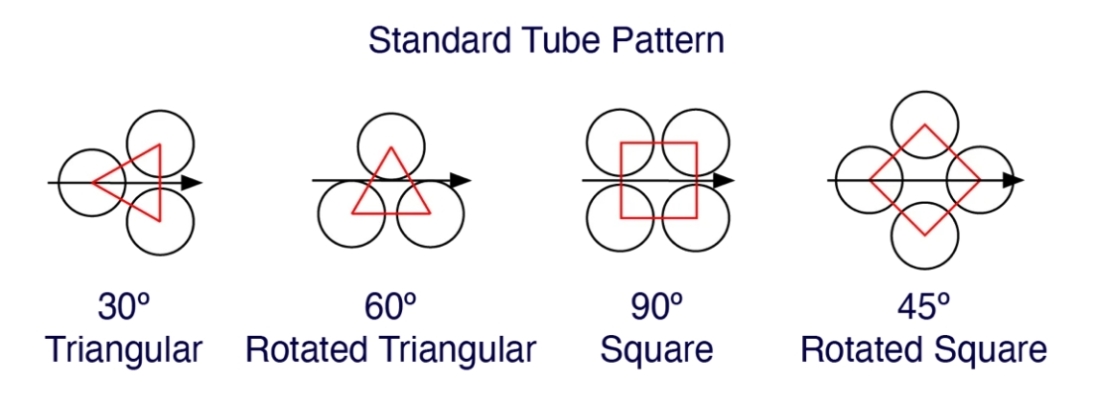

The arrangement of tube sheet holes has its own advantages. The equilateral triangle arrangement is compact, with a high degree of turbulence in the fluid outside the pipe and a large heat transfer coefficient. The square arrangement makes it easy to clean the outside of the pipe and is suitable for fluids that are prone to scaling.

The advantage of triangular arrangement is high heat transfer efficiency, with the highest number of tubes arranged on the same tube sheet area, about 15% more than square arrangement. However, it is not easy to clean the outer surface of the tubes, while square to 45 ° angle arrangement is more convenient for cleaning the outer surface of the tubes, but the number of tubes arranged is much less than triangular arrangement.

Whether it is processing 1.5mm small holes, or larger holes exceeding 100mm, or any customized hole type by customers, Wuxi Changrun relies on advanced equipments and rich service experience to achieve excellent drilling machine processing efficiency. There are also many successful service cases, and customer satisfaction is high.

Wuxi Changrun has advanced overlay welding technology and can provide customers with various customized weld overlay tubesheets according to their needs. Cladding materials can be provided, such as stainless steel, duplex steel, nickel based alloys, titanium materials, copper materials, etc.

The products provided by Wuxi Changrun, such as tube plates, flanges, and steel pipes, are applied in industries such as pressure heat exchangers, nuclear power, petrochemical, coal chemical, hydropower, thermal power, energy, and mechanical manufacturing.

Wuxi Changrun packages according to the customer's product size and uses waterproof plywood boxes suitable for sea transportation.

Materials:

| Carbon Steel & Alloy Steel |

ASTM A516 Gr.70, ASTM A105, ASTM A266 Gr.2, ASTM A182 F1, F2, F5, F9, F11, F12, F22, F6a, F6NM, F91, ASTM A350 LF1/LF2/LF6 |

| Stainless Steel & Duplex Steel |

ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254) ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L |

| Nickel & Nickel Alloy |

Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36 |

| Titanium & Titanium Alloy |

ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12 ASTM B381 F1, F2, F7, F12 |

| Copper & Copper-Nickel |

C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu) |

| Clad Materials |

Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding |

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet