What Are You Looking For?

Lagest Forging: 100MT.

Max OD of tube sheets: 8 Meters.

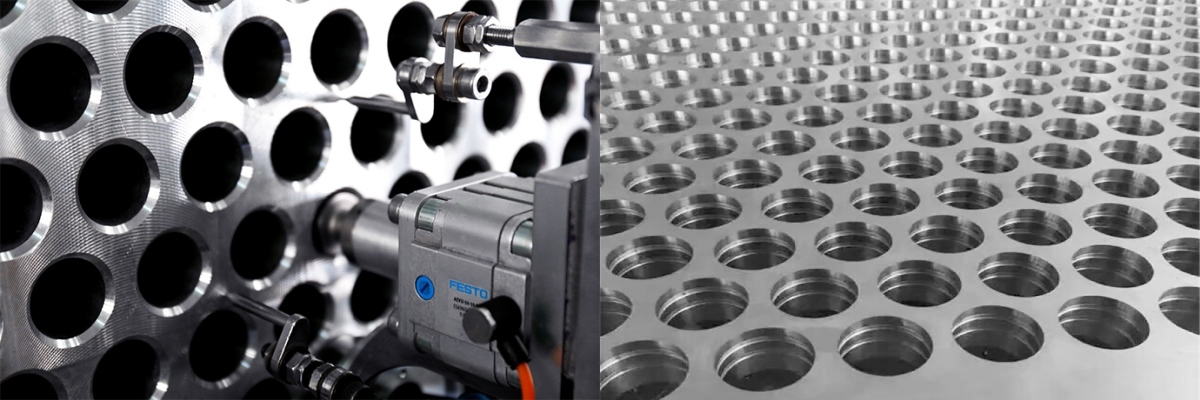

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Material: Monel 400

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

Wuxi Changrun can produce customized tube sheets and produce them 100% according to customer drawings. We have advanced drilling equipments that can serve the processing of tube sheets, including 11 deep hole drills, 31 CNC drills, and 11 CNC lathe equipment, to achieve precision tube plate machining services with high processing accuracy, complete specifications, and multiple functions.

Pressure vessel tube sheet is a plate structure located inside a pressure vessel to separate the two working media inside and outside the vessel, usually made of metal materials. Its function is to divide the interior of the pressure vessel into several independent areas to accommodate different working media or meet process requirements, thereby ensuring the safe operation of the vessel.

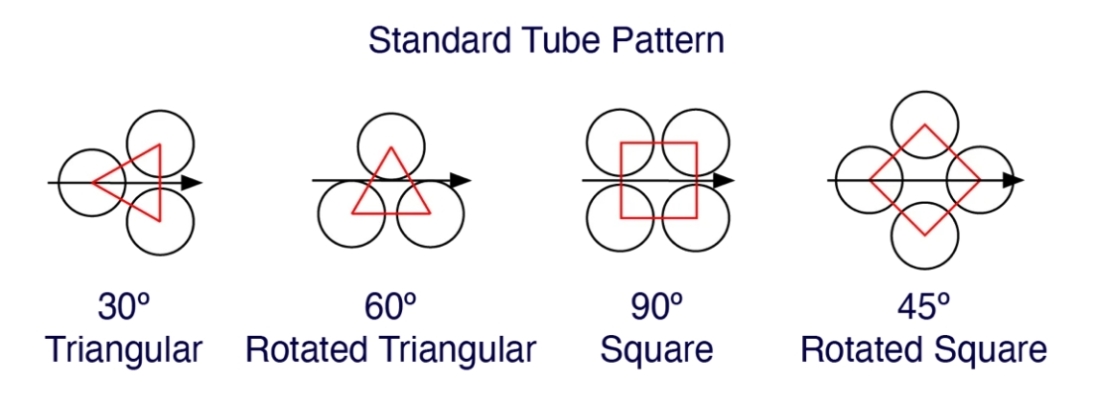

The arrangement of tube sheet holes has its own advantages. The equilateral triangle arrangement is compact, with a high degree of turbulence in the fluid outside the pipe and a large heat transfer coefficient. The square arrangement makes it easy to clean the outside of the pipe and is suitable for fluids that are prone to scaling.

The advantage of triangular arrangement is high heat transfer efficiency, with the highest number of tubes arranged on the same tube sheet area, about 15% more than square arrangement. However, it is not easy to clean the outer surface of the tubes, while square to 45 ° angle arrangement is more convenient for cleaning the outer surface of the tubes, but the number of tubes arranged is much less than triangular arrangement.

Whether it is processing 1.5mm small holes, or larger holes exceeding 100mm, or any customized hole type by customers, Wuxi Changrun relies on advanced equipments and rich service experience to achieve excellent drilling machine processing efficiency. There are also many successful service cases, and customer satisfaction is high.

Wuxi Changrun packages according to the customer's product size and uses waterproof plywood boxes suitable for sea transportation.

Materials:

Stainless Steel & Duplex Steel: ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254)

ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L

Nickel & Nickel Alloy: Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36

Titanium & Titanium Alloy: ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12, ASTM B381 F1, F2, F7, F12

Copper & Copper-Nickel: C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu)

Clad Materials: Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet