What Are You Looking For?

Tube sheets play a crucial role in various industrial applications, particularly in the manufacturing of equipment that involves heat transfer, fluid transportation, and pressure management. These flat plates with precisely drilled holes provide structural support and facilitate the integration of tubes or pipes. Here are some common applications of tube sheets:

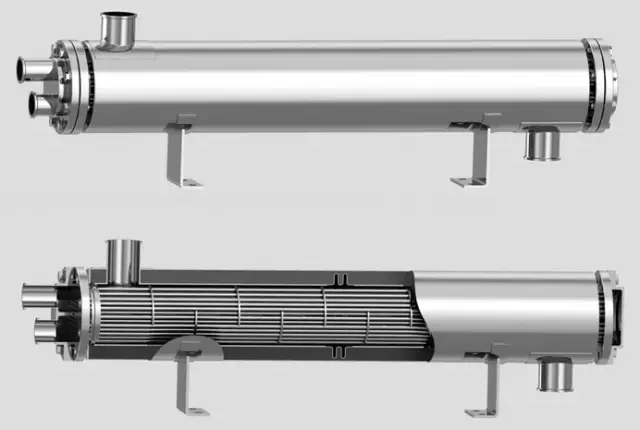

Heat Exchangers:

Tube sheets are extensively used in heat exchangers to connect and support heat exchange tubes. They enable the transfer and exchange of heat energy between different fluid streams, such as in oil refineries and chemical plants. Tube sheets also serve as a crucial element in maintaining the separation between different fluid streams within the heat exchanger. They create a barrier between the tubes carrying one fluid and the surrounding shell or chamber carrying another fluid. This separation is vital in applications where it is essential to prevent mixing or contamination of the fluids, such as in chemical processing or food industries.

Boilers:

Tube sheets are essential components in boilers, where they connect boiler pipes and water chambers. They contribute to the generation of steam or hot water by facilitating heat transfer within the boiler system. The heat transfer process in boilers relies on the tube sheets. The hot combustion gases generated during the fuel combustion flow over the outer surface of the tubes, transferring their heat energy to the water or steam within. This transfer of heat enables the conversion of water into steam, which can then be used for various industrial processes or for generating power in steam turbines.

Pressure Vessels:

Tube sheets play a critical role in the manufacturing of pressure vessels like gas storage tanks and reactors. They ensure the secure connection between the vessel walls and pipelines, allowing the vessel to withstand internal pressure safely. Tube sheet is one of the important components in pressure vessels, used to separate the cylinder and head of the pressure vessel, usually referred to as a "partition". The function of the tube sheet is to separate the fluid in the pressure vessel to ensure the normal operation and stability of the fluid inside the vessel. Multiple tube sheets are usually arranged inside pressure vessels to separate and control the fluid.

Condensers:

Tube sheets are vital in the production of condensing equipment. They connect the condensing pipeline and the refrigerant flow pipeline, enabling efficient heat dissipation and the conversion of vapor into liquid. The tube sheet acts on the middle pipeline of the condenser to reduce the deflection of the heat transfer tube and improve the vibration characteristics of the heat transfer tube during operation. It is usually designed to support the tube sheet that the middle of the heat transfer tube is higher than the two ends, which can reduce the thermal expansion stress of the heat transfer tube.

Chemical Equipment:

Tube sheet welding is employed in the construction of chemical equipment. It connects different process pipelines necessary for material transportation and processing in various chemical processes.

Electric Power Industry:

Tube sheet welding is utilized in the fabrication of boilers and power generation equipment, such as those found in steam power plants. Tube sheets ensure the reliable connection and efficient heat transfer within these systems.

Food and Beverage Industry:

Tube sheets are employed in heating and cooling equipment used in the food and beverage industry. They enable efficient heat transfer in food processing equipment and beverage filling systems, enhancing productivity and product quality.

Pharmaceutical Industry:

Tube sheets find applications in the manufacturing of various pharmaceutical equipment, including reaction vessels and distillation equipment. They provide the necessary connections for fluid transport and process control.

Overall, tube sheets are versatile components widely used in industrial equipment across different sectors. The welding techniques employed in tube sheet fabrication ensure sealing, stability, and pressure resistance, making them indispensable in numerous industrial processes. Whether it's for heat exchange, fluid handling, or pressure containment, tube sheets play a crucial role in optimizing the performance and efficiency of various industrial applications.

Wuxi Changrun is committed to providing high-quality tube sheets, baffles, nozzles, and flanges to global customers. The products produced by Wuxi Changrun are applied to world-renowned end customers, including: SINOPEC, CNPC, SHELL, BASF, CHEVRON, BAYER, MOBIL, BP, CNOOC, VESTAS, TOYO etc,.