What Are You Looking For?

Forged Tube Sheets Manufacturer Changrun Supplies Forged Tubesheet.

Lagest Forging: 100MT.

Max OD of tube sheets: 8 Meters.

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Material: SA182 F22

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

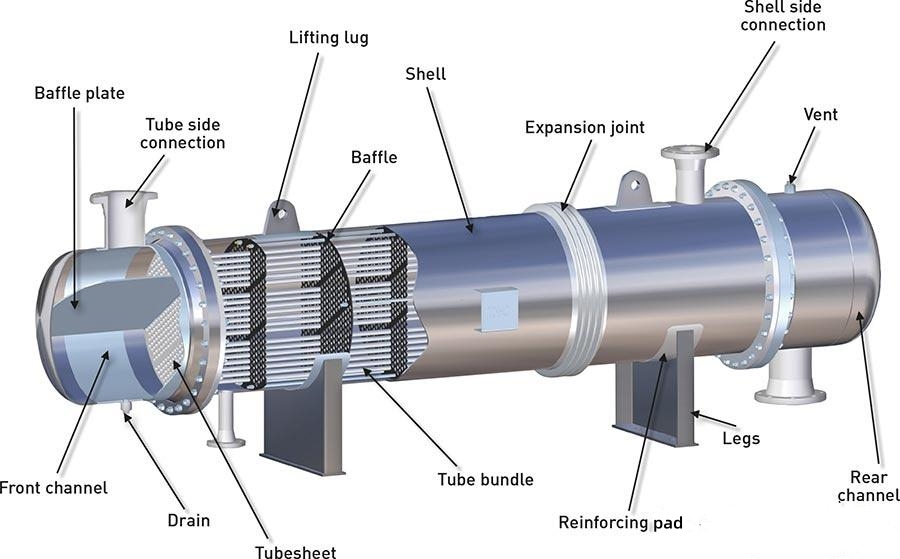

Tube sheets are most commonly used in heat exchangers and boilers. These devices are composed of tightly arranged thin-walled tubes, which are encapsulated within a tubular shell. The tube sheet plays a crucial supporting role by maintaining and positioning the tube in a predetermined pattern. Insert the tube through the corresponding hole in the tube plate and form a safe seal through different connection methods. The layout of the tube hole pattern, commonly referred to as "spacing", determines the distance between tubes, their angles to each other, and their direction related to the flow direction. This design flexibility allows for manipulation of fluid velocity, pressure drop, and effective heat transfer through maximum turbulence and pipe surface contact.

The Wuxi Changrun team has been constantly exploring and gradually adapting to the fast-paced delivery mode. From receiving orders to shipping, a mature supporting shipping mechanism has been formed: technical drawing- place order-planning and coordinating production-timely tracking production progress-adjusting production mode - packaging and packaging - warehouse loading and shipping. All departments work together and strive to deliver to customers on time with quality and quantity as quickly as possible.

Materials:

Stainless Steel & Duplex Steel: ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254)

ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L

Nickel & Nickel Alloy: Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36

Titanium & Titanium Alloy: ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12

ASTM B381 F1, F2, F7, F12

Copper & Copper-Nickel: C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu)

Clad Materials: Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet

Manufacturing Capacity:

Tubesheet (Tube Plate), Baffle, Support plate, Ring & Flange