What Are You Looking For?

Forged Tube Sheets Manufacturer Changrun Supplies Forged Tubesheet.

Lagest Forging: 100MT.

Max OD of tube sheets: 8 Meters.

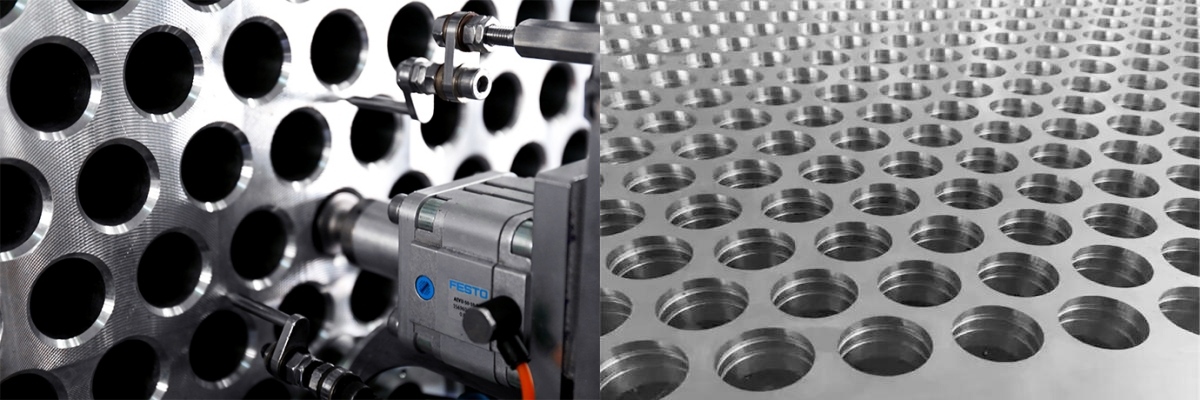

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Material: SA182 F1

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

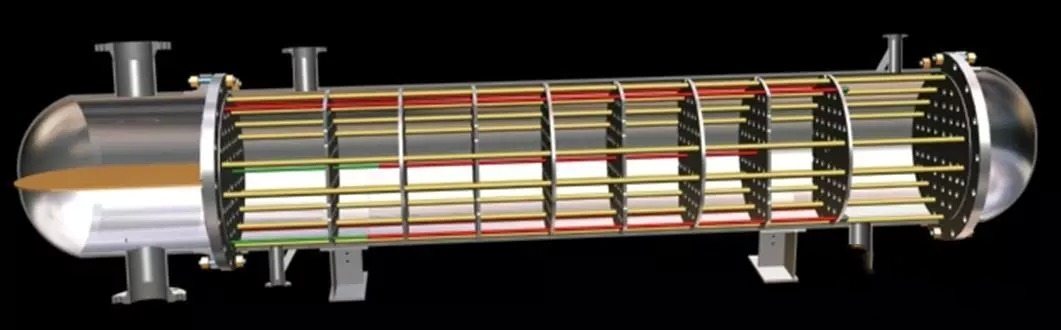

Tube sheets are most commonly used in heat exchangers and boilers. These devices are composed of tightly arranged thin-walled tubes, which are encapsulated within a tubular shell. The tube sheet plays a crucial supporting role by maintaining and positioning the tube in a predetermined pattern. Insert the tube through the corresponding hole in the tube plate and form a safe seal through different connection methods. The layout of the tube hole pattern, commonly referred to as "spacing", determines the distance between tubes, their angles to each other, and their direction related to the flow direction. This design flexibility allows for manipulation of fluid velocity, pressure drop, and effective heat transfer through maximum turbulence and pipe surface contact.

Tube sheet processing is an important process in the manufacturing of heat exchangers. The accuracy of tube plate processing, especially the spacing and diameter tolerance of tube holes, verticality, and smoothness, directly affects the assembly and performance of heat exchangers. The customer has put forward high requirements for product quality. Based on the characteristics of the product, Wuxi Changrun coordinated 4 CNC porous drills and lathes, combined with Wuxi Changrun's processing experience in tubesheet and baffle plate processing, and successfully completed the processing matching.

Whether it is processing 1.5mm small holes, or larger holes exceeding 100mm, or any customized hole type by customers, Wuxi Changrun relies on advanced equipments and rich service experience to achieve excellent drilling machine processing efficiency. There are also many successful service cases, and customer satisfaction is high.

Wuxi Changrun has many professional technical personnel in the processing of tube sheets. Through a series of mature process combinations such as welding, multi plate stacking drilling, stacked boring, shockproof tooling, and inclined angle drilling, it can provide technical support for irregular holes such as gemstone flower holes, tooth shaped holes, diamond shaped holes, and elliptical holes, in addition to common round holes. It can meet the diverse needs of customers and achieve customized services for their tube sheet products.

Materials:

Stainless Steel & Duplex Steel: ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254)

ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L

Nickel & Nickel Alloy: Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36

Titanium & Titanium Alloy: ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12

ASTM B381 F1, F2, F7, F12

Copper & Copper-Nickel: C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu)

Clad Materials: Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet

Manufacturing Capacity:

Tubesheet (Tube Plate), Baffle, Support plate, Ring & Flange