What Are You Looking For?

Forged WELD NECK FLANGE (WN Flange) Manufacturer Changrun Supplies Forged WN Flanges,

DN15-DN2000 (1/2-80 Inch),

150-2500 LB (PN6-PN420),

Wall Thickness: SCH 40.

Material: ASTM A815 UNS S32750.

Flange face: RF, FF, RTJ, TF, GF.

Certificates: CE, ISO, PED, TS, BV, CQC.

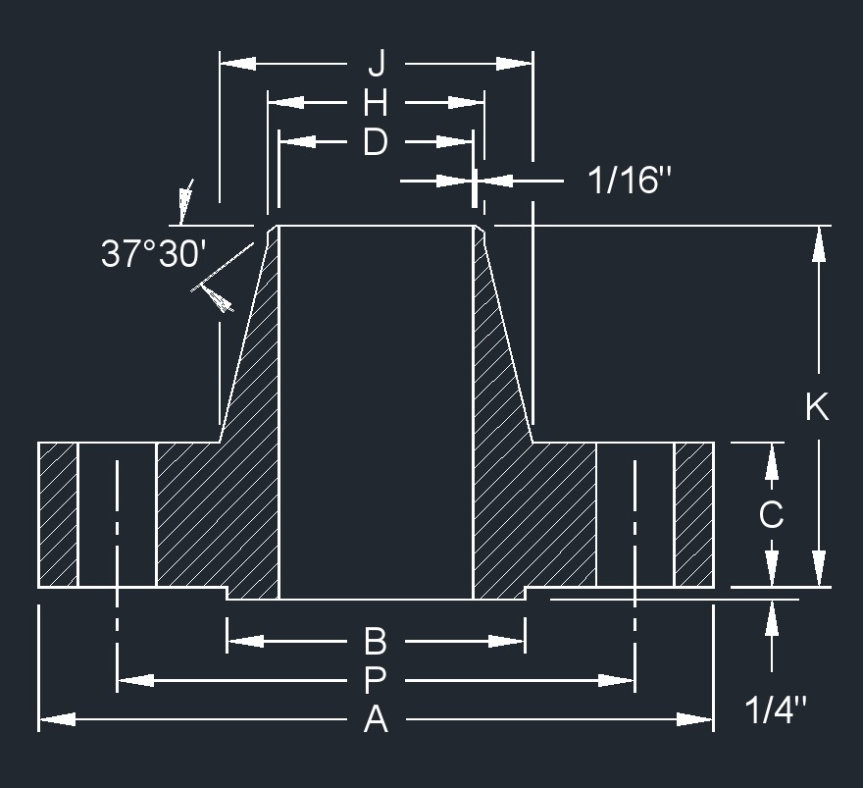

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant. A weld neck flange consists of a circular fitting with a protruding rim around the circumference. Generally machined from a forging, these flanges are typically butt welded to a pipe. The rim has a series of drilled holes that permit the flange to be affixed to another flange with bolts.

ASME B16.5 Class 2500 RF

Flanges play a crucial role in various industries and applications where the connection between pipes, valves, and equipment is required. The importance of flanges lies in their ability to provide secure connections, sealing, strength, flexibility, alignment, accessibility, standardization, and safety within piping systems. They are vital components that contribute to the efficient and reliable operation of various industries, including oil and gas, chemical, power generation, water treatment, and many others.

The neck welded flange (WN Flange) is suitable for various high-temperature and high-pressure pipeline systems, and its common functions include the following aspects:

1. Connecting pipelines: A weld neck flange is a type of pipeline connector commonly used to connect two pipelines used for transporting liquids or gases, serving as a connecting device to ensure the normal flow of liquids or gases.

2. Improve safety: Using welding neck flanges to connect pipelines can improve the safety and stability of the pipeline, and reduce the risk of leakage in the pipeline system.

3. Adaptation to high temperature and high pressure: The welded neck flange can withstand high temperature and high pressure, and is suitable for various high temperature and high pressure working environments to ensure the normal operation of the pipeline system.

Specification:

Size Range: DN15-DN2000, 1/2 Inch-80 Inch

Face Finish: RF, FF, RTJ, TF, GF

Standard & Pressure Ratings:

1. ANSI/ASME/ASTM B16.5/B16,47: 150 LB, 300 LB, 600 LB, 900 LB, 1500 LB, 2500 LB

2. DIN/UNI: PN6, PN10, PN16, PN25, PN40, PN64

Material:

A. Carbon Steel: ASTM A105, ASTM A350 LF1, ASTM A350 LF2, S235JR, P245GH, P250GH, P280GH, ASTM A694 F42, ASTM A694 F46, ASTM A694 F52, ASTM A694 F56, ASTM A694 F60, ASTM A694 F65, ASTM A694 F70, etc

B. Stainless Steel: ASTM A182 F304, ASTM A182 F304L, ASTM A182 F304H, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F317, ASTM A182 F317L, ASTM A182 F321, ASTM A182 F310, ASTM A182 F347, etc.

C. Alloy Steel: ASTM A182 F1, ASTM A182 F5, ASTM A182 F9, ASTM A182 F11, ASTM A182 F22, ASTM A182 F91, etc.

D. Duplex and super duplex steel: ASTM A815 UNS S31803, ASTM A815 UNS S32205, ASTM A815 UNS S32750, ASTM A815 UNS S32760

Service:

Surface Treatment: Black painting, anti-rust varnish, anti-rust oil, hot-galvanized

Non-destructive Testing: penetration test, ultrasonic test, radiographic test

Certificate: CE, ISO, PED, TS, BV, CQC Certificate

Packing: Plywood Case or Pallet