What Are You Looking For?

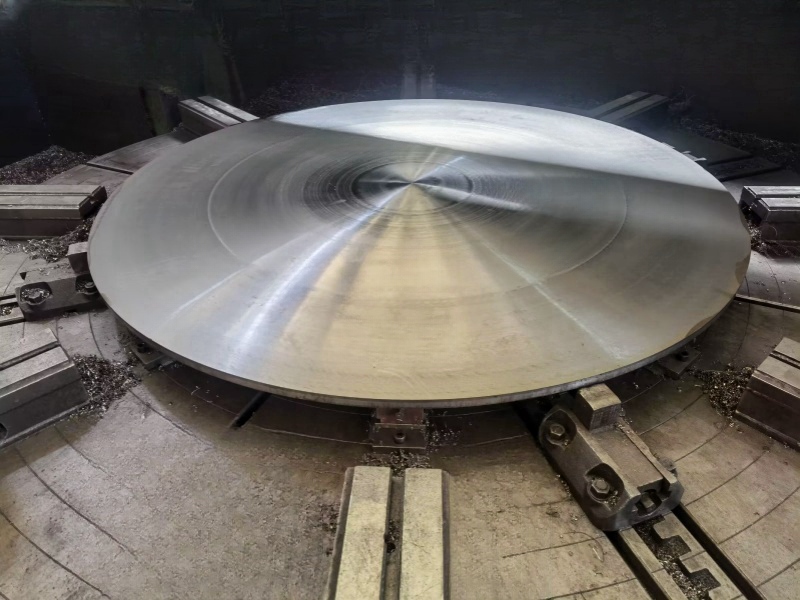

Lagest Forging: 100MT.

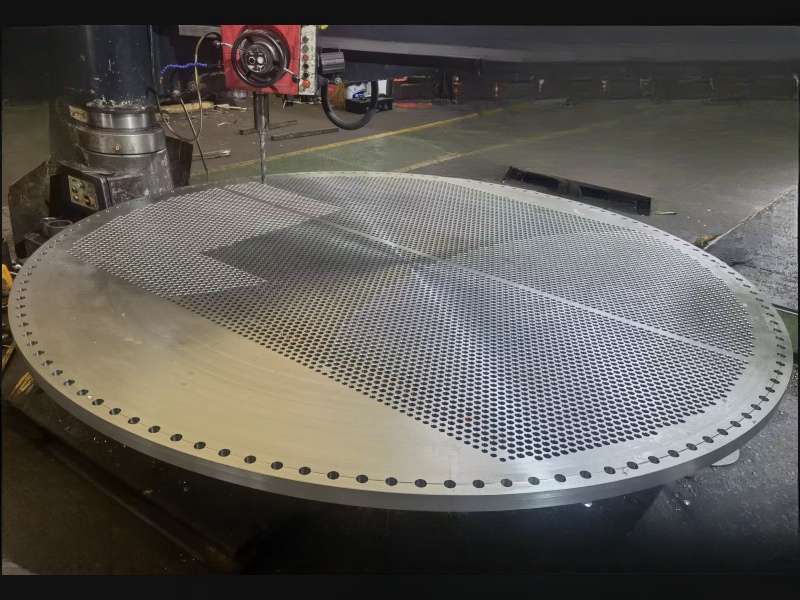

Max OD of tube sheets: 8 Meters.

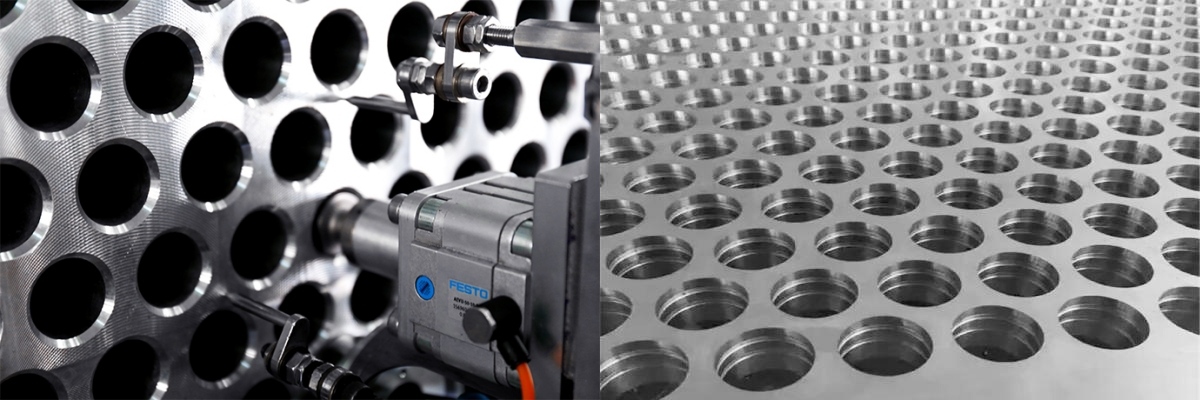

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Material: A182 F316/ f316L

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

Tube sheet products are widely used in industries such as seawater desalination, heat exchangers, pressure vessels, paper machines, petroleum smelting, steam turbines, nuclear power, etc. Wuxi Changrun has been committed to deep processing of tube plates since its establishment. After years of development, combined with the "one-stop" service concept of integrating steel materials and processing, it has created a unique service platform for tube sheet and baffle plate processing.

Wuxi Changrun has a maximum drilling depth of 1200mm, with a diameter greater than or equal to 12mm but less than or equal to 55mm. It has the characteristics of stable hole size, excellent hole wall roughness, and high perpendicularity. It can process tube sheets with a thickness of 1200mm, achieving double axis and triple axis processing, with an efficiency 2-3 times that of traditional processing methods.

Wuxi Changrun's requirement for tube sheet drilling is to achieve a smoothness of Ra Above 1.6 μm. It can also achieve a more perfect smoothness according to customer requirements. In addition, it is ensured that the drilling surface is free of defects such as burrs and cracks, meeting the requirements for surface flatness. If the smoothness of the drilling on the tubesheet does not meet the standard, it may affect the sealing effect, service life, and appearance quality of the tube plate.

Materials:

| Carbon Steel & Alloy Steel |

ASTM A516 Gr.70, ASTM A105, ASTM A266 Gr.2, ASTM A182 F1, F2, F5, F9, F11, F12, F22, F6a, F6NM, F91, ASTM A350 LF1/LF2/LF6 |

| Stainless Steel & Duplex Steel |

ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254) ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L |

| Nickel & Nickel Alloy |

Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36 |

| Titanium & Titanium Alloy |

ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12 ASTM B381 F1, F2, F7, F12 |

| Copper & Copper-Nickel |

C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu) |

| Clad Materials |

Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding |

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet