What Are You Looking For?

Material: A182 F304/ F304L

Dimension: 1200mm X 1200mm X 32mm,

Hole diameter: 12mm

Lagest Forging: 100MT.

Max OD of tube sheets: 8 Meters.

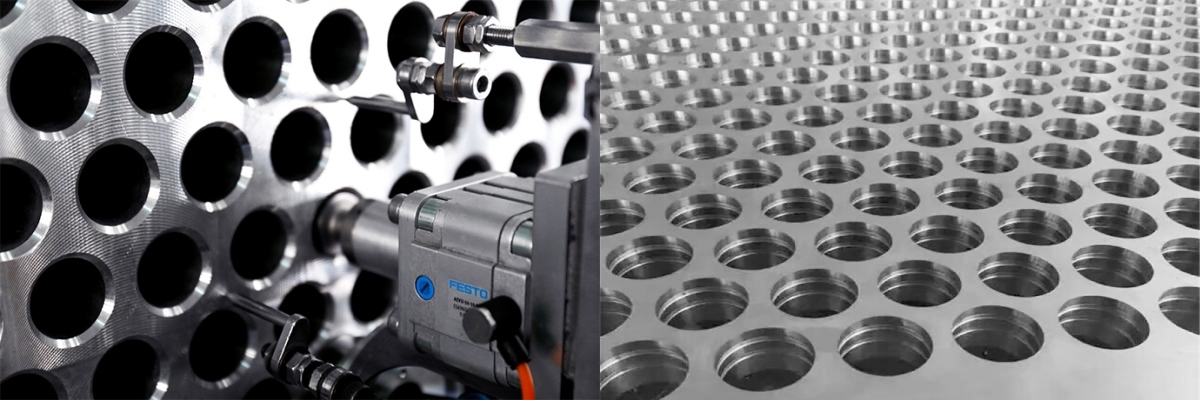

Tube hole details: positioning accuracy of up to 0.01mm, minimum aperture tolerance of 0.01mm, minimum roughness Ra0.6 in the hole.

Standards: ASTM, AISI, ASME, DIN, EN, AS, GB.

The tube sheet is one of the main components in a shell & tube heat exchanger. Depending on the tube bundle configuration, a heat exchanger can be equipped with one or two tube sheets. These are usually made of steel material, with a varying thickness based on the fluid pressure. Depending on the final application (petrochemical, nuclear, oil&gas, etc.) the tube sheet can be cladded with Stainless Steel or other Super Alloys or even be entirely made out Stainless Steel or Superalloys.

Tube sheet is a pressurized component in a heat exchanger, which is an important component of a channel that integrates support functions and achieves heat transfer. As a supporting component, the tube sheet is used to fix all tubes in their corresponding positions to ensure the stability and operational efficiency of the tubes; As one of the channels for heat flow media, the tube sheet can feed the medium inside the pipeline into the corresponding position of the heat exchanger to achieve heat transfer.

Whether it is processing 1.5mm small holes, or larger holes exceeding 100mm, or any customized hole type by customers, Wuxi Changrun relies on advanced equipments and rich service experience to achieve excellent drilling machine processing efficiency. There are also many successful service cases, and customer satisfaction is high.

Wuxi Changrun can efficiently process products in bulk and meet the personalized customization needs of customers. Wuxi Changrun has the standard configuration of CNC machines, advanced machining equipment such as large tabletop machines, multi hole drills, deep hole drills, and vertical lathes. The "one-stop" high-efficiency and fast delivery tube sheet processing provides strong support, truly helping customers achieve cost reduction and efficiency increase.

Materials:

| Carbon Steel & Alloy Steel |

ASTM A516 Gr.70, ASTM A105, ASTM A266 Gr.2, ASTM A182 F1, F2, F5, F9, F11, F12, F22, F6a, F6NM, F91, ASTM A350 LF1/LF2/LF6 |

| Stainless Steel & Duplex Steel |

ASTM A240 Gr.304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 310S, 310H, 310MoLN, 317L, 347, 347H, 904L, AL-6XN (N08367), Duplex 2205 (S31803 & S32205), Duplex 2507 (S32750), 410, 444, 253MA, 254SMO (S31254) ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F321, F321H, F310, F310H, F317L, F347, F347H, F20 (N08020), F44 (S31254), F51 (S31803), F53 (S32750), F60 (S32205), F62 (N08367), F904L |

| Nickel & Nickel Alloy |

Nickel 200, Nickel 201, Monel 400, Incoloy 800/800H/800HT/825/901/926, A-286, Inconel 600/601/625/718/X-750, Hastelloy B/B-2/C-4/C-22/C-276, Invar 36 |

| Titanium & Titanium Alloy |

ASTM B265 Gr.1, Gr.2, Gr.7, Gr.12 ASTM B381 F1, F2, F7, F12 |

| Copper & Copper-Nickel |

C46400, C61400, C70600 (10% Ni, 90% Cu), C71500 (30% Ni, 70% Cu) |

| Clad Materials |

Explosive Cladding(SS/CS, Ni/CS, Cu/CS, Ti/CS, Ti/SS, Cu/SS, Ni/SS, Ti/Cu, Ti/Ni) & Overlay Welding |

Service:

Main Test: chemical composition, mechanical properties, PT, UT, intergranular corrosion, composite strength, hardness, size, roughness.

Certificates: CE, ISO, ABS, DNV, LR, KR, PED, TS, BV, CQC.

Packing: Plywood Case or Pallet